published on 10/20/24

A bright meeting room overlooking the rooftops of the Unterschleißheim industrial area: the door opens, and CTO Marcus Gögelein enters the room. His team watches eagerly as he quietly places a small component on the table. It’s unassuming, only a few millimeters in size, but now it becomes the center of attention. ‘For this,’ Gögelein says, ‘we need a new solution.

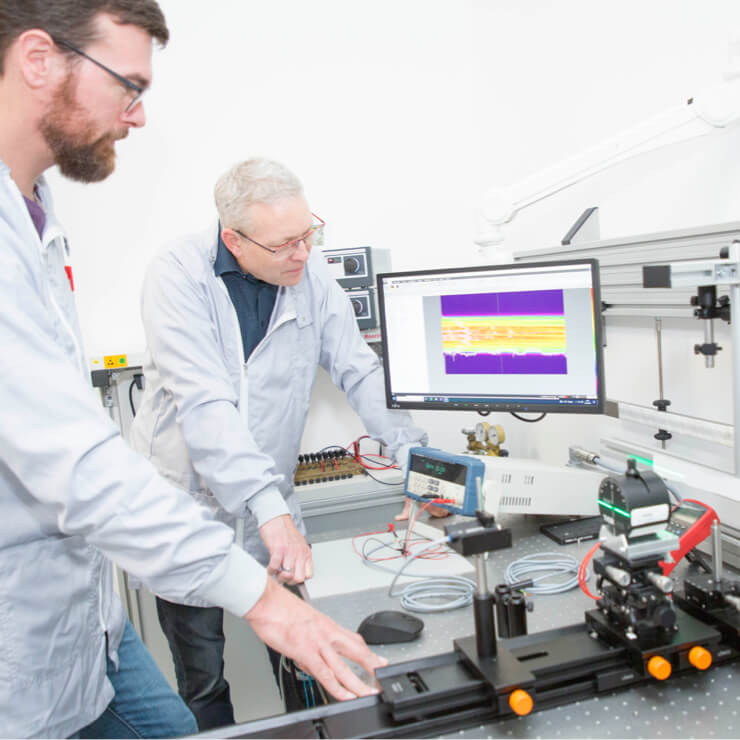

This is how many new projects begin at IMM Photonics in Unterschleißheim. The company specializes in developing and manufacturing custom solutions for clients, with a focus on lasers and optics used in fields such as medical technology, biotechnology, measurement technology, and data transmission. ‘In other words, we develop solutions for solutions,’ explains K. Julius Weder, the newest member of Gögelein’s development team.

Unique, Better, Flawless

Clients approach IMM Photonics for a variety of reasons. Sometimes it involves developing a completely new laser system based on a detailed performance and requirements specification. Other times, it’s about replacing an old, discontinued optoelectronic component—but not with a simple drop-in replacement. Instead, clients request a solution that also accommodates their additional, highly complex applications. Occasionally, it’s troubleshooting an existing design where a desperate client seeks help from the experts or manufacturing small and micro-series production runs.

Beyond Standards

At IMM Photonics, innovation is part of the daily routine. Whether it’s laser modules, collimators, LEDs, detectors, or driver electronics, standard solutions often fall short in solving the complex challenges that clients face. In other cases, standard solutions aren’t sufficient to create the innovative products that deliver added value and secure competitive advantage. Each project starts with specific client requirements and needs from various industries, which are carefully analyzed and adapted accordingly.

Path of Least Resistance

But how does the development team proceed from there? Is there some sort of tried-and-true formula? “At the beginning, it often starts with classic brainstorming,” explains Head of Development Gögelein. However, the process that follows is almost never the same, as it depends on the specific customer requirements.

The only thing you could maybe say,” reflects Weder, “is that development is essentially always about taking the path of least resistance, even if that might sound totally unglamorous at first.” He explains with an example: “If a requirement is minimal, I don’t need to jump straight into a large simulation. Say a client simply wants light to hit a specific shape, size, and distance in a very basic form – I can start by just putting a lens in front of a light source and checking: does the spot fit in the back?” In this case, rather than diving straight into calculations, the first question would be: Is there something comparable already available?

The Funnel Principle of Development

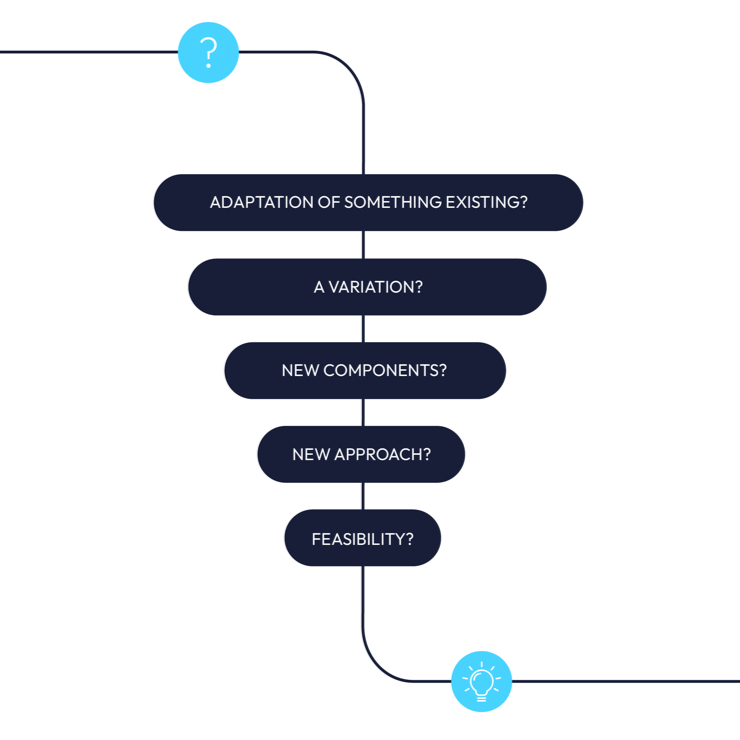

Overall, the two developers explain, the process can be compared to a funnel:

- Top level: The initial question is, “Do we already have something similar, and can we adapt it to what we need?”

- Second level: If that doesn’t work, they ask, “Can we modify something we already have?” If so, they proceed with that.

- Third level: The next filter is, “What exactly would we need to create from scratch to make it work?”

- Fourth level: Then comes, “If we were to think completely innovatively and design something new, would the effort be worth it economically?”

- Fifth and final level: Finally, they assess the physical feasibility, because, as Gögelein and Weder know, “sometimes the laws of nature simply don’t cooperate, and even the greatest creativity and experience have their limits.

Because Innovation Takes Effort

Only if at least one of these levels can be answered with a “yes” is the project considered feasible and worthwhile. The funnel model also clearly illustrates that innovation can occur at various levels, ranging from simple “recombination” at the top to complete redevelopment. “The effort we have to put in increases with each level,” Gögelein explains, adding, “This shows clearly: innovation always requires effort. I think that’s often overlooked with this buzzword. True innovation needs money, time, thought, trials, and errors.”

From Idea to Economic Viability

But what exactly is “true” innovation? “Since people don’t really invent anything new but instead create new relationships and connections, every innovation is ultimately a recombination. The more unknowns there are in what we’re developing, the more innovation is needed and/or possible,” says Weder, adding, “For me, ‘true’ innovation is a recombination of existing modules with very, very few data points.”

Accordingly, the funnel acts as a kind of gradient that helps Gögelein’s team determine if the effort they put in aligns with the client’s goals. This ensures from the start that clients only incur the necessary costs. At IMM, it’s never about ideas for their own sake, but rather about enabling new processes and technologies or improving existing ones.