published on 10/20/24

A bright meeting room overlooking the rooftops of the Unterschleißheim industrial area: the door opens, and CTO Marcus Gögelein enters the room. His team watches eagerly as he quietly places a small component on the table. It’s unassuming, only a few millimeters in size, but now it becomes the center of attention. ‘For this,’ Gögelein says, ‘we need a new solution.

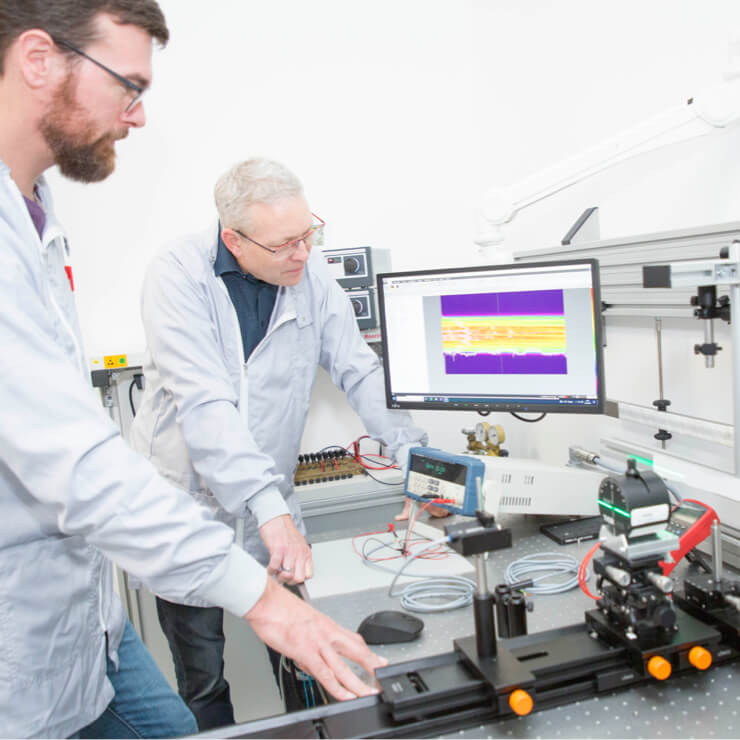

This is how many new projects begin at IMM Photonics in Unterschleißheim. The company specializes in developing and manufacturing custom solutions for clients, with a focus on lasers and optics used in fields such as medical technology, biotechnology, measurement technology, and data transmission. ‘In other words, we develop solutions for solutions,’ explains K. Julius Weder, the newest member of Gögelein’s development team.

Unique, Better, Flawless

Clients approach IMM Photonics for a variety of reasons. Sometimes it involves developing a completely new laser system based on a detailed performance and requirements specification. Other times, it’s about replacing an old, discontinued optoelectronic component—but not with a simple drop-in replacement. Instead, clients request a solution that also accommodates their additional, highly complex applications. Occasionally, it’s troubleshooting an existing design where a desperate client seeks help from the experts or manufacturing small and micro-series production runs.

Beyond Standards

At IMM Photonics, innovation is part of the daily routine. Whether it’s laser modules, collimators, LEDs, detectors, or driver electronics, standard solutions often fall short in solving the complex challenges that clients face. In other cases, standard solutions aren’t sufficient to create the innovative products that deliver added value and secure competitive advantage. Each project starts with specific client requirements and needs from various industries, which are carefully analyzed and adapted accordingly.

Path of Least Resistance

But how does the development team proceed from there? Is there some sort of tried-and-true formula? “At the beginning, it often starts with classic brainstorming,” explains Head of Development Gögelein. However, the process that follows is almost never the same, as it depends on the specific customer requirements.

The only thing you could maybe say,” reflects Weder, “is that development is essentially always about taking the path of least resistance, even if that might sound totally unglamorous at first.” He explains with an example: “If a requirement is minimal, I don’t need to jump straight into a large simulation. Say a client simply wants light to hit a specific shape, size, and distance in a very basic form – I can start by just putting a lens in front of a light source and checking: does the spot fit in the back?” In this case, rather than diving straight into calculations, the first question would be: Is there something comparable already available?

The Funnel Principle of Development

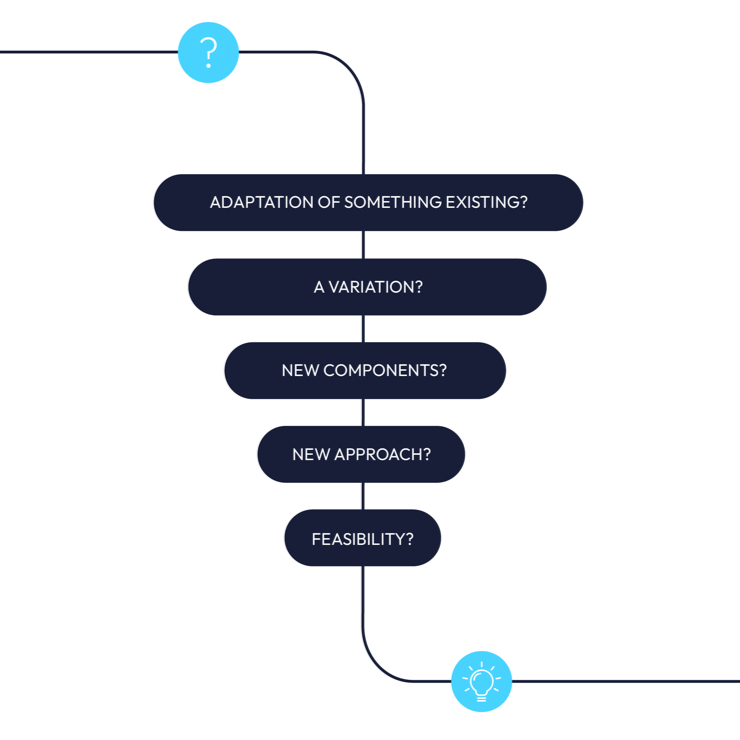

Overall, the two developers explain, the process can be compared to a funnel:

- Top level: The initial question is, “Do we already have something similar, and can we adapt it to what we need?”

- Second level: If that doesn’t work, they ask, “Can we modify something we already have?” If so, they proceed with that.

- Third level: The next filter is, “What exactly would we need to create from scratch to make it work?”

- Fourth level: Then comes, “If we were to think completely innovatively and design something new, would the effort be worth it economically?”

- Fifth and final level: Finally, they assess the physical feasibility, because, as Gögelein and Weder know, “sometimes the laws of nature simply don’t cooperate, and even the greatest creativity and experience have their limits.

Because Innovation Takes Effort

Only if at least one of these levels can be answered with a “yes” is the project considered feasible and worthwhile. The funnel model also clearly illustrates that innovation can occur at various levels, ranging from simple “recombination” at the top to complete redevelopment. “The effort we have to put in increases with each level,” Gögelein explains, adding, “This shows clearly: innovation always requires effort. I think that’s often overlooked with this buzzword. True innovation needs money, time, thought, trials, and errors.”

From Idea to Economic Viability

But what exactly is “true” innovation? “Since people don’t really invent anything new but instead create new relationships and connections, every innovation is ultimately a recombination. The more unknowns there are in what we’re developing, the more innovation is needed and/or possible,” says Weder, adding, “For me, ‘true’ innovation is a recombination of existing modules with very, very few data points.”

Accordingly, the funnel acts as a kind of gradient that helps Gögelein’s team determine if the effort they put in aligns with the client’s goals. This ensures from the start that clients only incur the necessary costs. At IMM, it’s never about ideas for their own sake, but rather about enabling new processes and technologies or improving existing ones.

Partner for laser components

5 key criteria developers should consider when choosing a manufacturer

News & Insightspublished on 10/24/24

Whether at the university, in the lab, or in a company, anyone looking for a specific laser component for innovative projects often feels like they’re searching for a needle in a haystack. Frequently, the only option is to have the part custom-made. But who can be relied upon? Here, we’ve outlined five criteria to help you choose the right design and manufacturing partner.

From mechanical engineering and measurement technology to medical technology and bioanalytics, all these industries require custom solutions in laser, fiber optics, UV & UVC tailored to specific demands. For critical applications, standard products rarely provide the necessary precision, performance, or functionality. In such cases, specialized manufacturers are needed—those who can precisely meet customer requirements and offer development, design, prototyping, and production all under one roof.

But what sets one specialized provider apart from another? In this blog post, we’ve compiled five practical criteria that significantly contribute to customer satisfaction and long product lifecycles.

1. Find a sales team that speaks your language

The first point of contact between you and your potential contractor is the sales team, where the groundwork for a successful and straightforward collaboration is already laid. It’s essential that your contact listens carefully, asks the right questions, and understands your requirements precisely. Ideally, the salesperson you’re speaking with has a technical background and a solid understanding of your needs.

Additionally, ensure that the development department is involved in your project at an early stage to evaluate the assignment from their specialized perspective. In this phase, all requirements and needs are reviewed, questioned, and refined in detail. This creates transparency and the highest possible planning security for both sides. Such a process is especially advantageous if you already have a finished design that needs production or optimization, as it allows for early identification of potential weaknesses, avoiding costly trial-and-error or unnecessary detours.

2. Keep manufacturing in mind from the outset

Similar advantages come from choosing a partner who not only supports your photonics project through the design and prototyping phases but can also guide it into series production. In such companies, manufacturing expertise feeds back into the development department. Through comprehensive support, the team keeps feasible manufacturing methods — both existing and new — in mind right from the start. This approach minimizes potential issues at the critical handoff from prototyping to series production. With continuous iteration and close collaboration, valuable synergies can be achieved.

If it only becomes clear later that a component cannot be implemented as planned due to manufacturing constraints, adjustments will need to be made. This almost inevitably leads to compromises that could impact both the quality and lifespan of your product.

Therefore, whenever possible, place development and manufacturing in the same hands. This increases the likelihood of receiving design proposals for lasers or optics that are truly feasible.

3. Plan for the long term

While development times in the consumer sector are often short, with production sometimes winding down after just one to three years, specialized applications in fields like medical technology, bioanalytics, and similar areas often require extended lead times. These can span around 10 years or more before the product reaches series production. For such an investment to pay off, the product must also remain on the market for a similarly extended period. For instance, IMM Photonics has been manufacturing one product for a client for nearly 30 years, with plans for it to remain in use for another two decades. If your project falls into a similar category, it’s essential to seek a manufacturer from the start who can ensure stability over long timeframes. These are usually well-established companies with a longstanding client base.

Depending on the market, components not only need to be available long-term but must also meet exceptionally high standards for durability. Factors like component selection, construction method, and cleanliness during production all impact longevity. Therefore, it’s essential to clarify your lifetime requirements for the product early in the engagement process. Additionally, outline the environmental demands the product must withstand in daily use. If necessary, the manufacturer should be capable of subjecting your prototype to specific stress, vibration, or climate cycle tests.

4. Researching for speed

On the other hand, you may need to react quickly to new technologies and market trends. In this case, it’s important to address your expectations for time-to-market promptly. When speaking with different providers, ask them to illustrate typical timelines from product concept to market launch using example projects.

What qualifies as a fast or slower timeline naturally depends on the product’s complexity. Experienced manufacturers like IMM Photonics can design a simple collimator in about a week. After customer approval, it moves into production, and within roughly four weeks, you’ll have the first product developed specifically for you in hand. For highly complex, highly integrated systems, the timeline can easily extend to one and a half to two years.

5. Adhere to purity standards

Particle contamination is a major challenge in the optics field. In measurement applications, even the smallest particles within a module can significantly impact product quality and measurement accuracy — a risk that should ideally be avoided with a cleanroom.

There are two options for this: Flow boxes, a type of mini cleanroom, already provide enhanced cleanliness for optics. A more advanced step in cleanliness and quality is a dedicated, fully enclosed cleanroom specifically classified for the production of optical components. With specialized airflow technology, particles are even more effectively removed from the workspace.

This setup prevents even the smallest deposits on optical surfaces. Access to these cleanrooms is controlled through personnel airlocks, where specialized cleanroom attire is worn. Additionally, strict environmental conditions are maintained; temperature, humidity, and air pressure are precisely regulated to create optimal conditions for assembling optical components. Our tip: Address cleanliness requirements early in the engagement process and inquire about the specific measures taken to ensure particle-free production.

Conclusion

Typically, you won’t find sufficient information on all these criteria on potential partners’ websites. It’s best to schedule an initial consultation with the manufacturers you’re considering and address your questions in person.

published on 11/01/24

Competitive pressure from Asia, challenges with global supply chains, and a shortage of skilled workers, especially in STEM fields: Christian Raith took on the leadership of IMM Photonics in challenging times. We spoke with him about his strategic approach and vision.

Mr. Raith, you took over the leadership of IMM Photonics in the midst of the COVID crisis and initially worked alongside your father for three years. Since early 2023, you have been the sole managing director. What changes has this brought?

Christian Raith: One of the first things I tackled, together with the second level of management, was a strategy process across all departments. We asked ourselves, ‘How can we reposition the company? How can we develop it further, both externally and internally?’ As part of this, we launched a series of modernization initiatives, some of which are already taking effect, while others are still in progress.

Which of these are already visible externally today?

I think the most important point is that we are shifting our focus. My father came from a distribution background, so during my parents’ time, the emphasis was on selling standard products in the fields of lasers, fiber optics, and other optics, UV, and UVC, which were then customized according to customer needs. Now, both the markets and our expertise have changed significantly.

We have become specialists in highly integrated custom solutions, with a particular strength in working with industries that have especially high demands for quality and longevity. We will continue to develop in this direction, focusing on even more complex and customized solutions. We aim to be increasingly recognized as a provider in this area moving forward.

What does that mean specifically: Can you share more about the products you will produce in the future?

“I would love to, but since we design and manufacture new solutions based on specific customer orders, it’s challenging to predict these future products. Additionally, we are bound by strict confidentiality agreements. What I can say, however, is where our focus will lie—in the field of life sciences, including bioanalytics, biomedicine, and medical technology. Other key areas are measurement technology, gas detection, and fiber optics.”

Why these industries specifically?

“Photonics is in demand across many fields. But when I have a choice as an entrepreneur, I prefer areas that are positively impactful and serve life and sustainability. This direction is largely value-driven. In addition, we see clear strengths in these areas; as I mentioned, we’re able to meet the high standards for quality, durability, and longevity that companies in these fields require. Being a trained bioengineer, I also bring personal expertise in medical technology and bioanalytics. Economically and in terms of future prospects, these fields are highly promising: we’re living longer, and maintaining good health is a universal concern. This growing need is worth investing in.”

Can you provide a specific example of a medical technology application?

“A vivid example is the rapid heart attack detection device used in ambulances. If there’s a suspected heart attack, a single drop of blood in this new device is enough. It measures a fluorescence signal, and within moments, the paramedic knows the risk level. In critical cases, they call ahead to the hospital so the operating room can be prepared immediately. This saves valuable time and significantly improves patients’ survival chances.

And fluorescence is where you come in?

Exactly. We supply the laser that triggers the fluorescence. The entire device is built by our client, who has been distributing it worldwide for a long time. There are certainly over 100,000 devices in use. We also provide components for MRIs and CT scanners, which also play a crucial role in detecting various diseases.

In addition, our laser and optical solutions support modern systems for PCR mass testing, which played a crucial role in assessing developments during the COVID-19 pandemic. And these are just a few examples from the field of medical technology.

You mentioned a series of modernization initiatives at the beginning. What internal changes are coming at IMM Photonics?

A key factor for us is advancing the company’s digitalization. For instance, we’re working on integrating our existing digital processes in material requirements planning with new digital applications, like production planning and automated measurement data collection. There’s also great potential to use AI here to analyze and make effective use of the hundreds of thousands or even millions of data points we’ll gather. Our goal is to simplify life for both our clients and our workforce. For example, we could make measurement data available to the client, facilitating their production processes. For our employees, this data can help identify and eliminate sources of error.

Another focus for me is sustainability. We’ve already set a lot in motion here and are continually working on improvements. We’ve transitioned our entire fleet to e-mobility and are steadily advancing our ratings on the internationally recognized EcoVadis sustainability platform.

A significant issue in technical industries is the shortage of skilled workers in STEM fields. How are you addressing this?

This is indeed a major challenge, and we’re tackling it from various angles. It starts with modernizing our company and leadership culture: we’re committed to collaboration at all levels, prioritizing approachability, participation, and a positive attitude toward mistakes. It’s very important to us that our employees can easily balance work and personal life, so we place high value on providing as much flexibility as possible. In Unterschleißheim, everyone can choose between working remotely or in the office, with a range of scheduling options. We create numerous opportunities for employees to contribute and develop professionally. Key areas that we have long supported are generational transitions and the related knowledge transfer. And, last but not least, we’re intensifying our commitment to developing young talent by expanding our in-house training to include technical fields, starting in 2026.

In closing, a brief outlook. How do you assess your market prospects for the next ten years?

Very positively, as we are in a sector that continuously opens up new possibilities, and there is still a long way to go. The entire segment is booming, leaving enough market share for everyone. This is also reflected in the general atmosphere, which remains very collaborative, even when dealing with competitors. It’s a field where collaboration takes precedence over cutthroat competition. Finally, we’re fortunate to have clients who proactively and innovatively push forward new ideas and rely on IMM Photonics to do so.