SPIE Photonics West 2026

Why VCSEL Innovation Requires Tailored Solutions — and Why Standard Approaches Are Reaching Their Limits

News & Insightsveröffentlicht am 29/01/2026

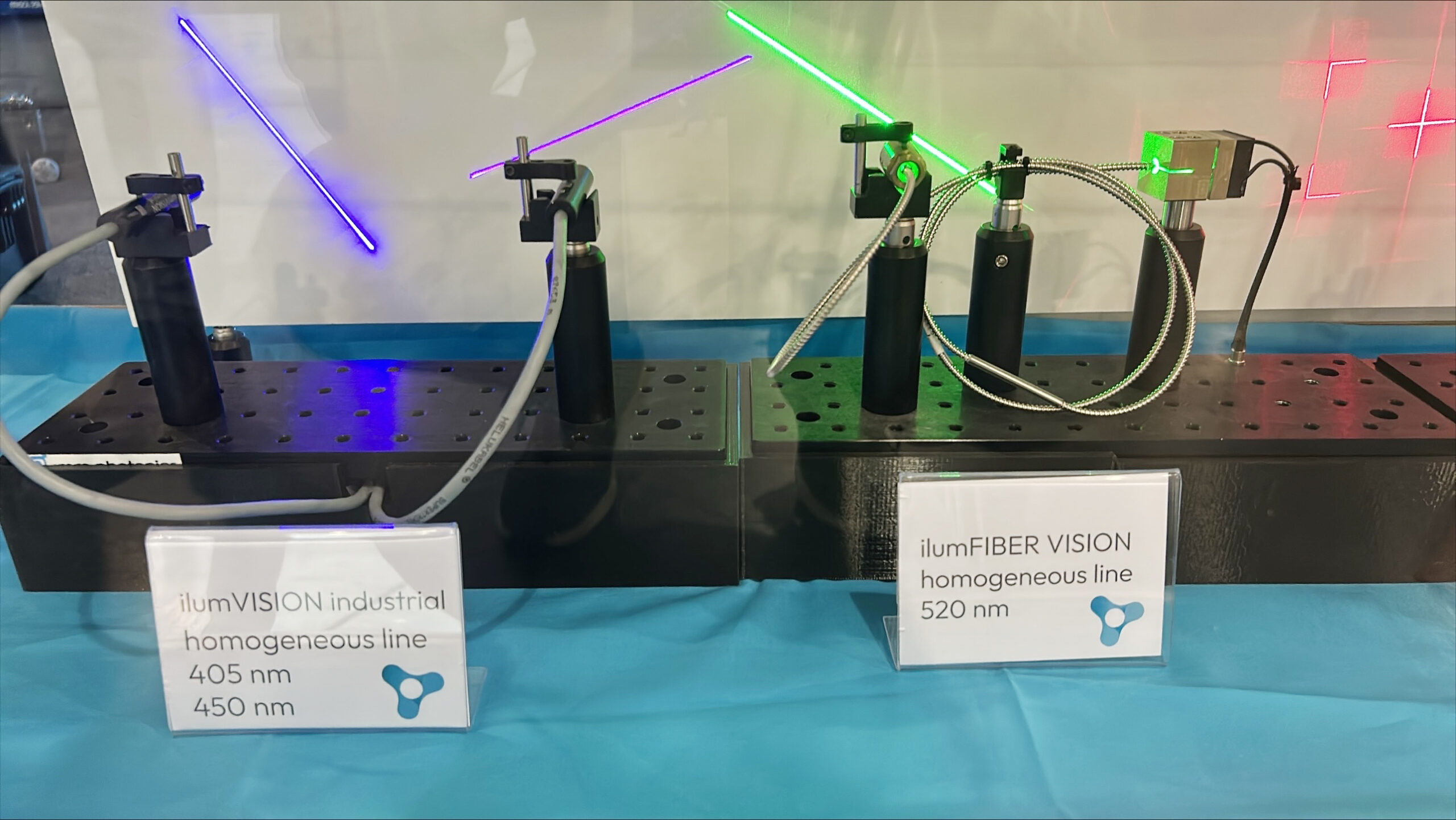

San Francisco, packed exhibition halls, and an international audience from industry, research, and engineering: SPIE Photonics West 2026 once again highlighted how rapidly photonics is evolving — and how strongly the focus has shifted toward application-driven VCSEL solutions. Instead of standardized components, custom, integrated laser designs are increasingly at the center of technical discussions.

This is exactly where IMM Photonics positions itself: beyond standard components.

Together with our partner Electro Optical Components, Inc., we were at Booth #4828 to demonstrate how VCSEL technology can serve as a scalable platform for customized laser and system-level solutions.

In real-world applications, success is no longer determined solely by a standard VCSEL datasheet. Performance, reliability, and repeatability are achieved through the interplay of VCSEL design, optics, packaging, and system integration.

VCSEL Technology in Transition: From Standard Components to Application-Specific Solutions

Conversations across the show made one thing clear: VCSELs are increasingly engineered to be application-specific. Requirements from industrial manufacturing, medical technology, sensing, and emerging UV applications can only be addressed to a limited extent with “one-size-fits-all” approaches.

Across numerous technical discussions, five core topics emerged — themes we see frequently in current development programs and that drew particularly strong interest at Photonics West:

-

Customized VCSELs as the foundation for application-specific laser design

→ tailoring emission wavelength, aperture, divergence, mode structure, and power density -

Performance and reliability through design optimization

→ thermal management, epitaxial design, packaging, and long-term stability as key levers -

Fiber-coupled VCSEL solutions and precision fiber optics

→ critical for robust systems with high repeatability, e.g., in sensing or industrial metrology

-

UV and UVC VCSELs for new industrial use cases

→ growing relevance for analytics, biotechnology, materials processing, and disinfection -

Optics and beam shaping

→ defined beam profiles, uniform intensity distributions, and stable spot geometries under real operating conditions

These topics underscore a central point: VCSEL technology reaches its full potential only when it is engineered consistently for the target application.

Booth Talk: How VCSEL Design Creates Measurable Competitive Advantages

One highlight was our VCSEL Booth Talk with Dr. Karthik Suresh Iyer. The discussion focused on how application-driven VCSEL design and custom laser subsystems enable targeted improvements in system performance — instead of forcing compromises with standard components.

Key discussion points included:

-

How VCSEL design parameters can be aligned with system requirements early in the development process

-

The role of optical and fiber integration in efficiency, stability, and scalability

-

Why custom VCSEL solutions are often more cost-effective than seemingly low-cost standard components

The key takeaway:

Customized VCSELs are no longer niche — they are a critical enabler of functional differentiation and sustainable competitive advantage.

From Trade Show to Development: Conversations as a Starting Point

We’d like to thank everyone who visited our booth, engaged in technical discussions, shared concrete requirements, and brought new ideas to the table. Special thanks to Electro Optical Components, Inc. for a strong and successful joint presence at the show.

For us, one thing is clear:

The conversations in San Francisco are the beginning — not the end.

If you’re currently working on custom VCSEL or laser diode solutions, precision fiber coupling, optical integration, or application-specific laser design, we’d be happy to continue the conversation. Together, we develop solutions that go beyond standard approaches — technically and economically.

Explore more related content here: https://imm-photonics.de/en/standard-solutions/laser/singlemode-vcsel-850-nm/

A PERSONAL CONVERSATION Feel free to call us or send us an email via the following link Contact

Inclusion That Connects

Visiting: Teisnacher Werkstätten of Lebenshilfe Deggendorf e.V.

News & Insightspublished on 10/28/25

How can inclusion be successfully achieved in the workplace?

An impressive example of this is the cooperation between the Teisnacher Werkstätten workshops run by Lebenshilfe Deggendorf e.V. and IMM Photonics.

Inclusion that connects

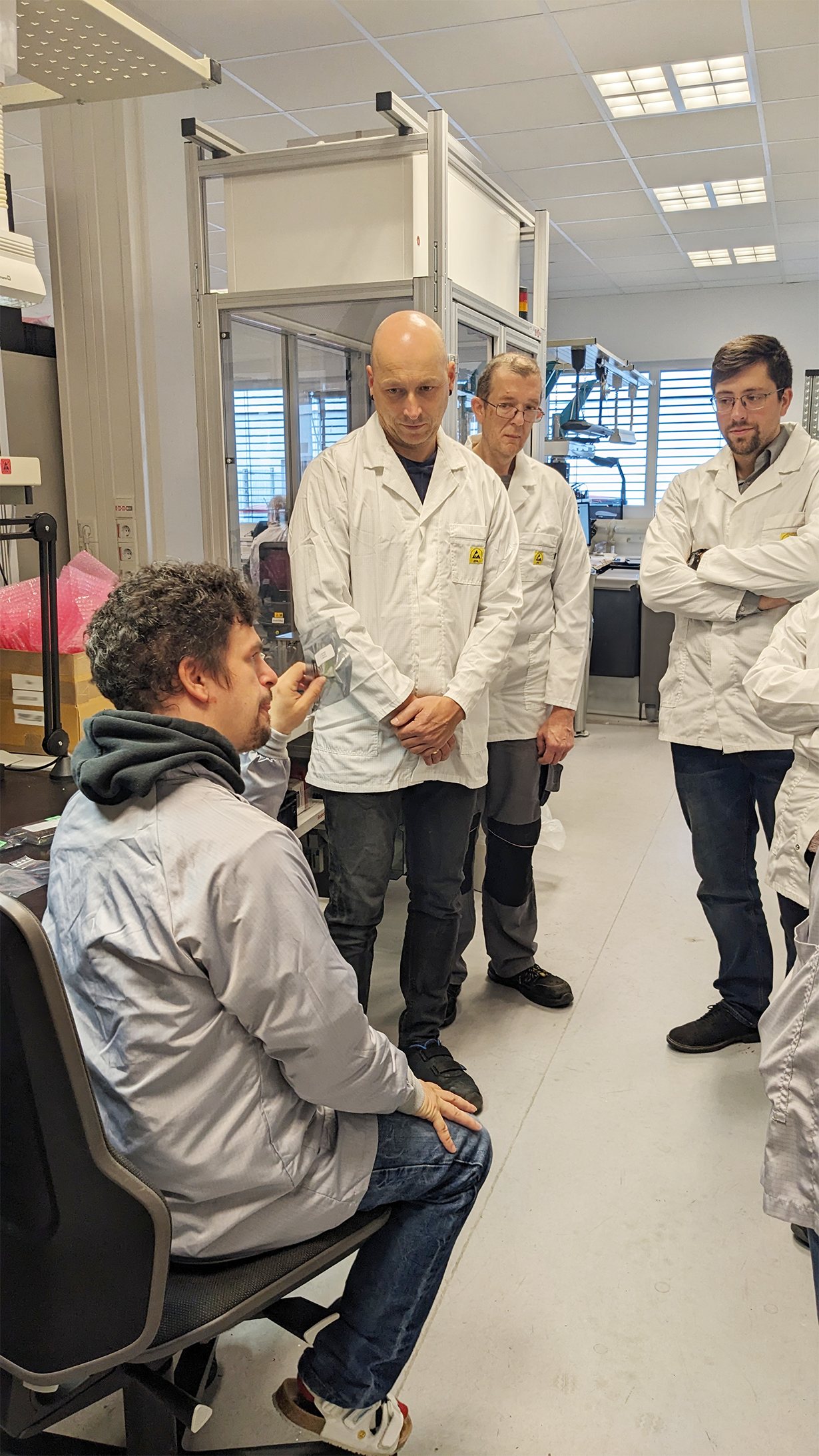

As part of a joint exchange at the IMM Photonics site in Teisnach, employees and staff from the Teisnacher Werkstätten visited Kevin’s workplace on October 21, 2025. Kevin is employed by the Teisnacher Werkstätten of Lebenshilfe Deggendorf e.V. and works at an outsourced workplace at IMM Photonics as part of a cooperation agreement. It’s a win-win situation: Kevin gains valuable professional prospects outside the workshop, and the IMM Photonics team gains a committed supporter and enriching addition in Kevin.

The visit made it clear that inclusion in practice is much more than just a concept: it arises when people take responsibility together, live in trust, and recognize individual strengths.

A day full of insights and valuable encounters

The group of visitors was welcomed by Christian Pritzl, Chief Operating Officer at IMM Photonics. During a tour of the modern production areas, the guests gained exciting insights into the company’s manufacturing technology. They were able to experience first-hand how innovative solutions are integrated into complex components with the highest precision and technical expertise. It became clear how much expertise and care goes into every single step of the manufacturing process.

The visitors were particularly interested in an automated adjustment system with robot technology and the highly sensitive clean room area, which is accessible via a special airlock. Through a large glass pane, the visitors were able to observe the precise work of the specialists – an impressive moment that made their appreciation and respect for the work on site palpable.

“The work in our production department requires a high degree of precision, concentration, and patience. Thanks to their many years of experience, our employees contribute these skills in an impressive manner.”

Precision, responsibility, and pride in one’s work

The information that a built-in laser is capable of detecting damage to a fiber optic cable up to four kilometers long during an optical inspection caused quite a stir—proof of the exceptional accuracy and quality that sets IMM Photonics apart.

Kevin also took the opportunity to present his work. With great commitment and skill, he demonstrated how laser diodes are prepared for production. Using practical examples, Kevin explained the correct use of ESD protective bags and emphasized that care, cleanliness, and a sense of responsibility are indispensable values in daily work.

Cooperation on equal terms – opportunities for all

The close proximity of the Teisnacher Werkstätten and IMM Photonics – both physically and in terms of people – stands for responsibility and active partnership. The cooperation is a prime example of how inclusion in the workplace can succeed when it is based on openness, respect, and trust – and that diversity in the workplace has long been a reality.

Conclusion: Practicing inclusion means more than integration – it creates genuine participation, mutual understanding, and sustainable prospects.

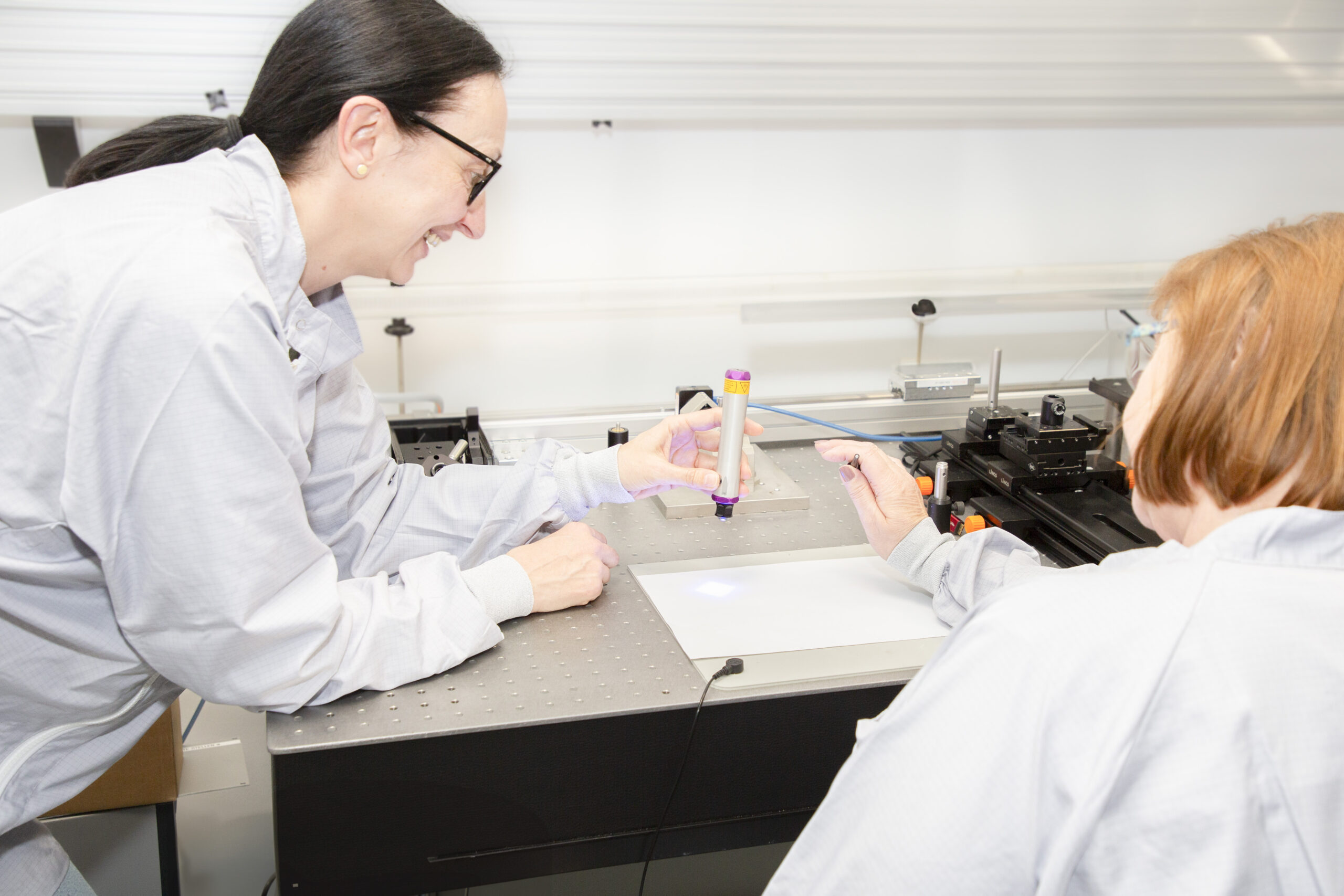

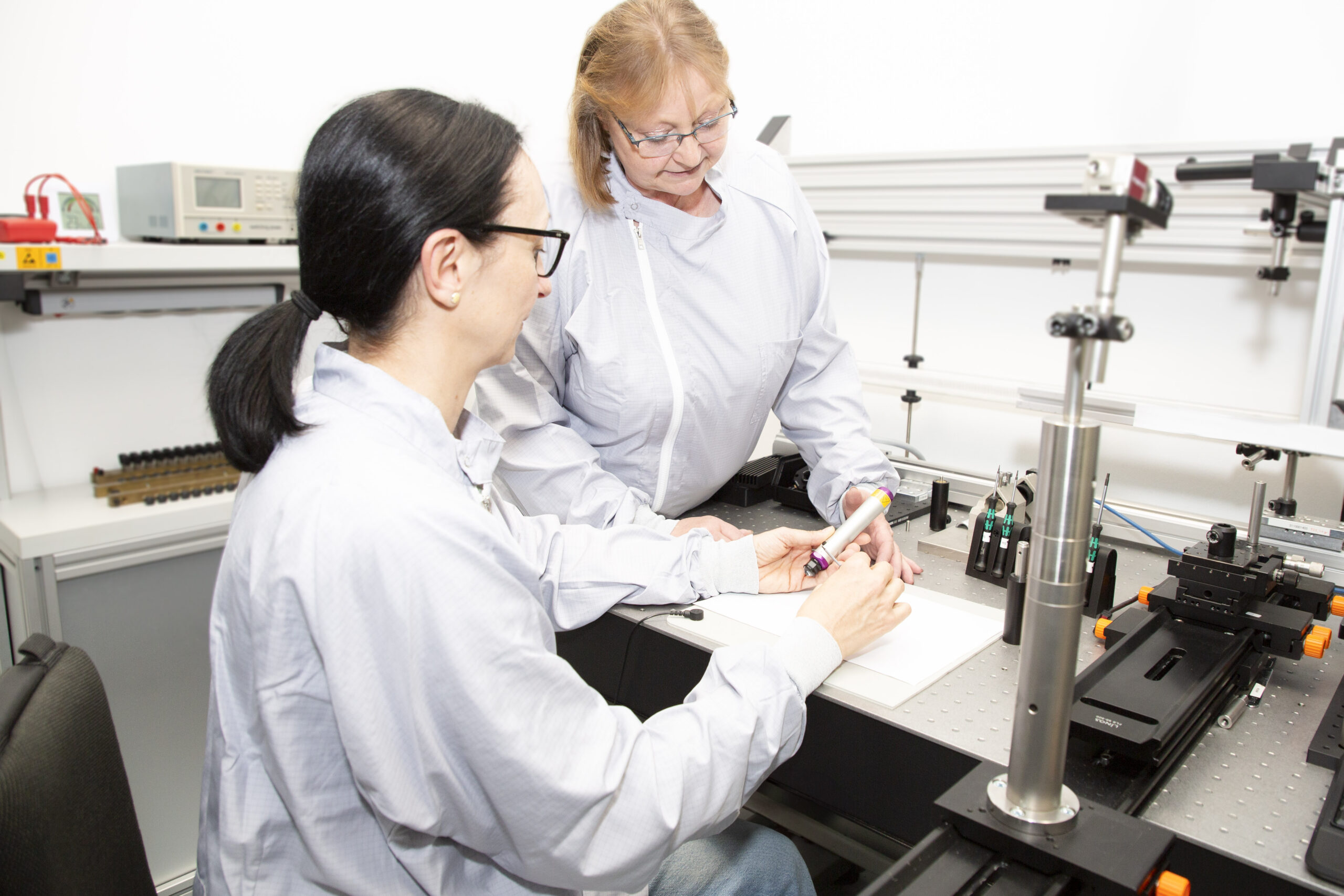

From Production to Leadership. Women in Photonics

How Sandra Schwürzinger Conquered the Laser World at IMM Photonics

News & InsightsPublished 09/09/2025

One Woman. One Company. One Passion for Technology.

When you talk to Sandra Schwürzinger, one thing becomes clear right away: she’s a doer.

A Gut Feeling – and the First Step into Laser Technology

A woman who took charge of her own career – and shows what female success can look like in high-tech environments.

And that in a field long considered a male domain: photonics.

In 2000, Sandra walked into the production hall of IMM Photonics back in those days, in Viechtach – not as an engineer, not as a manager, but as a production floor employee.

From her place on the production, the world of laser technology, optical systems, and custom photonic components seemed abstract at first. But what Sandra discovered wasn’t just a job – it was a world full of opportunity.

I had no idea how lasers worked, but I was curious. And that curiosity was nurtured at IMM Photonics.

Discovering a Passion: From Hands-On Work to a Bachelor’s Degree

What began in a production role soon evolved into a full-fledged passion for technology.

With IMM Photonics’ support, Sandra completed her technical diploma, and later her Bachelor of Engineering – while working full time. She studied after hours, wrote papers on weekends, and found consistent guidance in her mentor, Christian Pritzl.

Meanwhile, her career grew step by step:

From production, to development, to digital transformation

Today, Sandra is responsible for digital innovation at IMM Photonics and is part of the extended leadership team.

It’s not about being promoted because I’m a woman. It’s about being taken seriously – just like anyone else.

IMM Photonics: Where People – and Careers – Can Grow

IMM Photonics develops and manufactures:

- Custom optical interconnects

- Laser sources

- Fiber optics and assemblies

- Integrated photonic modules

But most importantly: it builds an environment where people can thrive.

Sandra’s journey is more than a personal success story – it exemplifies a corporate culture that fosters genuine growth.

Why IMM Photonics Stands Out

Work–life balance that works: Employees can bring their children to work when needed—showing true flexibility, especially for working moms.

Collaboration beats hierarchy: Progress is a team effort – and every door is open along the way.

Continuous learning is encouraged: Flexible work and further education is actively supported at IMM Photonics.

Equality in action: Gender and age don’t define career paths – skills and mindset do.

Production with purpose: Women lead in areas such as fine assembly, soldering, and fiber connector bonding – many of them coming from non-technical backgrounds like hairstyling or crafts.

We don’t hire perfect resumes – we train based on potential.

“Just Go For It”: Sandra’s Message to Future Female Engineers

To many, technology still speaks with a male voice. But to Sandra, it’s a space full of curiosity, opportunity, and growth – especially for women.

That’s why her advice is clear:

“Just go for it. Be curious. Don’t overthink it.”

She’s not alone: colleagues like Nicole Stern, currently earning her own technical diploma, are already following in her footsteps.

Through programs like Girls’ Day, IMM Photonics helps inspire the next generation of women in photonics and engineering.

Final Thought: Where Laser Precision Meets Passion

IMM Photonics proves that technical excellence and human-centered leadership go hand in hand.

This is a place where laser solutions for industrial applications are developed – and where careers shine just as brightly.

Like Sandra Schwürzinger’s:

Once a production line worker – now a digital leader helping shape the future of laser technology at IMM Photonics.

Looking to grow your career in photonics? Explore career opportunities at IMM Photonics.

A PERSONAL CONVERSATION Feel free to call us or send us an email via the following link Contact

Published 01/07/25

In a world in which technologies are becoming increasingly complex and challenges more global, photonics solutions play a decisive role – without being in the spotlight.

At IMM Photonics, we work to create concrete added value with customized photonics solutions. With our individual solutions, we do not supply “off-the-shelf” technology, but targeted answers to customer-specific applications.

We develop and produce customer-specific laser modules, optical and optoelectronic components, LED systems and fiber optic solutions for a wide range of applications. Our solutions are precise, efficient and sustainable and are often used where they are not even visible at first glance.

Industry solutions for practical applications

Whether in digitalization, food inspection, the automation of industrial processes or in medical technology – our products make their contribution wherever reliability, precision and sustainability are required.

For example: our FIBERPOINT® series fibre optic testers help with fibre continuity testing and fibre breakage detection, enabling precise fault location and minimizing downtimes. They therefore make a decisive contribution to the construction and maintenance of modern fiber optic networks and at the same time help to reduce energy-intensive data transmissions via copper.

Our solutions – precise, efficient, sustainable

In the food industry, our laser systems support modern inspection systems: purity, sorting according to ripeness or packaging control – all this is done with the highest precision.

Stationary or for mobile use: with our high-precision UV curing systems from the ilumCURE series, UV adhesives can be cured particularly efficiently and reliably in industrial production processes – for greater process stability with reduced energy consumption.

Precision in alignment: Our laser modules support the precise set-up of complex production systems and ensure that systems function smoothly from day one. This saves set-up time, avoids errors and increases efficiency.

Laser-based sensor technology also plays a role in the early detection of heart attacks. Our optical systems help to make life-saving diagnostics faster and more reliable – further proof that photonics can be vital.

All of this shows that photonics is a key technology for many of the most pressing issues of our time – from sustainability to automation and healthcare.

A PERSONAL CONVERSATION Feel free to call us or send us an email via the following link Contact

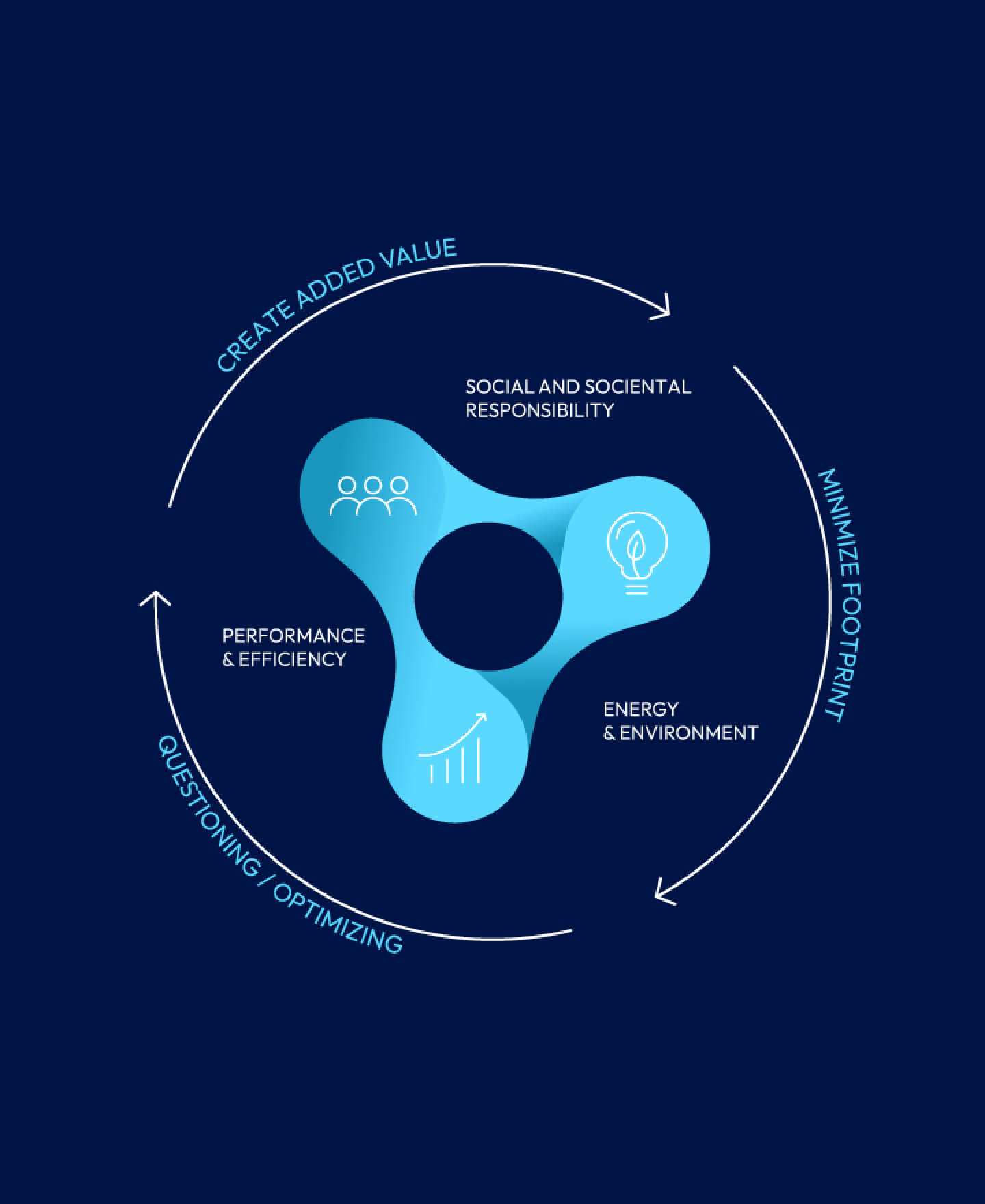

Sustainability with Substance

IMM Photonics Receives the EPIC Sustainability Award 2025

News & InsightsPublished 15/04/2025

A bright meeting room above the rooftops of Munich. On the table, a small, crystal-clear glass cube – the EPIC Sustainability Award 2025. Christian Raith, CEO of IMM Photonics, proudly accepts the accolade.

“This recognition sends a strong message – to our team, our partners, and the entire industry,” he says.

Why was IMM Photonics selected?

Because it’s not about isolated initiatives – it’s about a comprehensive transformation across all levels of the company.

Sustainability as a Strategic Pillar – Since 2015

IMM Photonics has pursued a consistent sustainability policy since 2015. One clear result: in 2023, the company reduced its CO₂ emissions by over 45% compared to the previous year. Switching to 100% green electricity at the Teisnach site and introducing energy-saving LED lighting at all locations are just a few of the milestones achieved.

Resource Conservation and Efficiency in Daily Operations

In production, mercury-based lamps have been replaced with UV LEDs. An in-house water purification system saves thousands of PET bottles each year. Motion sensors help reduce unnecessary energy consumption, and nearly the entire company fleet now runs on electric vehicles.

What’s the tangible impact?

A measurable reduction in environmental footprint and operational costs – and a working model for sustainable industry practices in the mid-sized business sector.

Responsibility Beyond Factory Walls

At IMM Photonics, sustainability also includes social responsibility: with company-sponsored retirement plans, employer-funded health insurance, and full flexibility in choosing the place of work. Suppliers are equally required to commit to fair working conditions, ethical conduct, and environmental responsibility.

Bottom line: Sustainable business requires sustainable leadership – both internally and externally.

On the Path to EcoVadis Gold Status

After receiving the Silver Medal in the 2024 EcoVadis sustainability rating, IMM Photonics has set its sights firmly on Gold for 2025. The roadmap includes: A further 30% reduction in CO₂ emissions; less packaging waste through internal process optimization; extended product lifecycles via reduced complexity; increased use of reusable packaging.

Recognition from the Industry – and Momentum for the Future

“This award is visible proof that our strategy is working,” says CEO Christian Raith.

Carlos Lee from EPIC adds:

“IMM Photonics is demonstrating how companies can become role models through their own initiative – benefiting not only the environment and society, but also enhancing their competitive edge.”

Those who take responsibility earn trust – and stand out in the market long term.

Sustainability as a Competitive Advantage

Partner with a company that not only talks the talk, but walks the walk – every single day.

Have a look on our YouTube video: EPIC Sustainability Award Film

A PERSONAL CONVERSATION Feel free to call us or send us an email via the following link Contact

Girls’ Day – Girls’ Future Day 2025

Project for career and study orientation for girls

News & InsightsPublished 10/04/2025

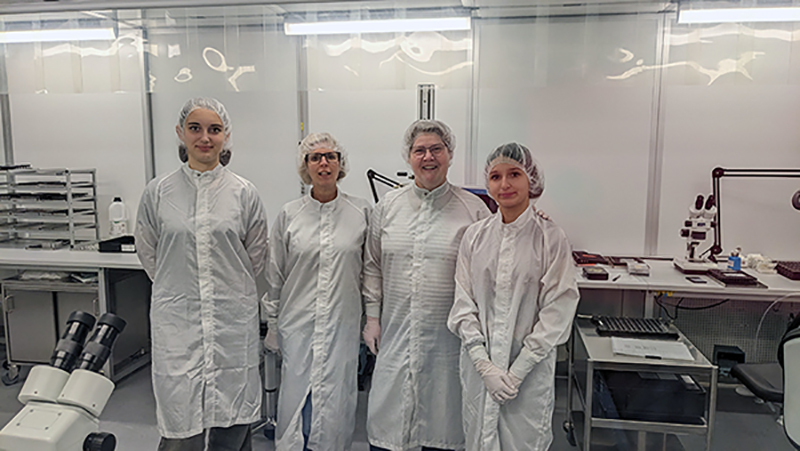

On April 3, 2025, two schoolgirls experienced an exciting Girls’ Day at our plant in Teisnach.

An unforgettable day: Girls’ Day at IMM Photonics

With a warm welcome from Christian Pritzl, Chief Operating Officer, we started Girls’ Day at our plant in Teisnach full of anticipation!

Both schoolgirls were welcomed with open arms and given an exciting tour of the plant. An important safety briefing was on the agenda, which also included valuable information on ESD protective clothing. After all, safety first!

Cleanroom adventure: a look behind the scenes

Equipped with special cleanroom clothing, the girls went into the ISO 6 class cleanroom. Here, the schoolgirls learned about the special requirements and working methods of a cleanroom.

Their manual skills were also put to the test, as they were allowed to try their hand at gluing lenses under the strict cleanroom conditions. A real adventure for the young talents!

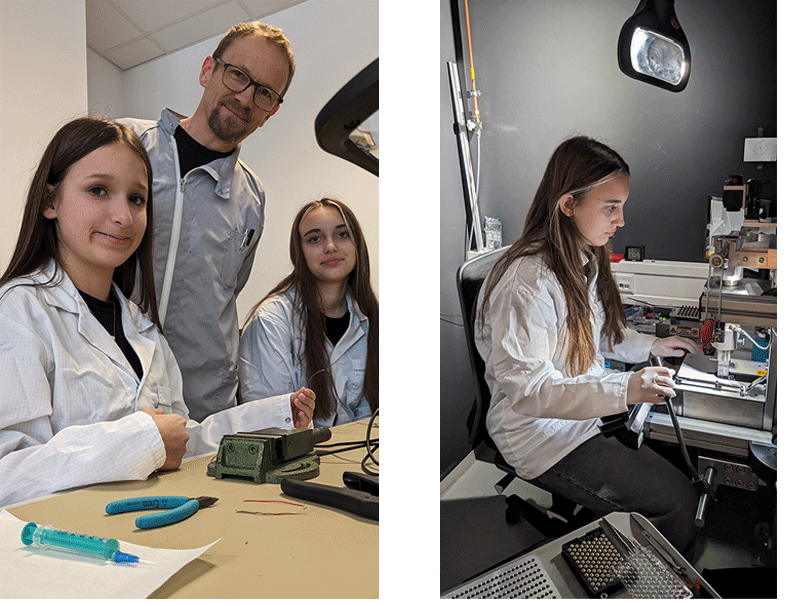

A little refreshment and then off to the collimators!

After a well-earned break during which they fortified themselves with delicious buttered pretzels, the girls were full of energy to work on collimators. They had the opportunity to understand how these important optical components work and how they are constructed, and to get hands-on themselves. It was impressive how quickly they got to grips with the material!

A great moment – soldering with skill and precision

The highlight of the day was soldering! Here the participants were able to demonstrate their skill and precision by making their own workpieces. A real feeling of pride and success – when they held their creations in their hands! To round off the day, the girls received their self-made workpieces and promotional materials as a memento of this special day.

We are proud of the great achievements of our Girls’ Day participants and hope that they will take many inspiring impressions home with them!

veröffentlicht am 18.02.25

After IMM Photonics received the bronze medal in a sustainability assessment by EcoVadis at the beginning of 2024, a new assessment was carried out at the beginning of this year, resulting in an impressive silver medal.

This puts IMM Photonics in the top 15% of companies that have had their sustainability performance assessed by EcoVadis in the last 12 months.

The silver medal is not only a sign of the company’s commitment to acting responsibly, but also an important step towards a more sustainable future.

“Sustainability is an issue close to our hearts at IMM Photonics and we are proud of the progress we have made in such a short time”

EcoVadis is a globally recognized provider of sustainability ratings for companies and has a network of over 150,000 rated companies. The ratings are based on a comprehensive set of criteria: Environment, Labor and Human Rights, Ethics and Sustainable Procurement.

IMM Photonics uses the results of the regular EcoVadis assessments to continuously improve its sustainability performance and thus invest further in sustainable solutions.

Published on 11/12/24

County Executive Dr. Ronny Raith, Chief Operating Officer Christian Pritzl, Teresa Sitzberger from the County Economic Development Office, and Mayor Daniel Graßl are excited about the planned site expansion.

Teisnach. Near the Teisnach Technology Campus, IMM Photonics has established itself as an innovative company renowned for its quality and technical precision. Recently, County Executive Dr. Ronny Raith, Teresa Sitzberger from the County Economic Development Office, and Mayor Daniel Graßl visited the production site to gain firsthand insight into the company.

After being provided with special protective clothing designed to guard against electrostatic discharge, Chief Operating Officer Christian Pritzl guided the guests through the production facility. During the tour, he explained the company’s various operational areas and introduced its product portfolio.

Since its founding in 1992, IMM Photonics has been synonymous with innovative and durable high-tech solutions “Made in Germany.” The family-run business, now led by Christian Raith in its second generation, develops laser and fiber optic components as well as optoelectronic systems. With its diverse product portfolio, IMM Photonics serves key industries such as industrial applications, medical technology, sensors, life sciences, and data communications.

Our county boasts tremendous potential, and the businesses located here can absolutely compete in quality with the world market leaders.

While development and sales are based in Unterschleißheim near Munich, manufacturing is centered at the Teisnach location. Across both sites, the company employs a total of 56 staff members—with further growth on the horizon. “In the future, we aim to provide in-house training in manufacturing and develop our talent directly within the company,” explained Pritzl. The apprenticeship program for “Industrial Mechanic with a Focus on Precision Instrument Manufacturing” is already in the planning stages in collaboration with the Chamber of Industry and Commerce (IHK). Among the 18 women working in production in Teisnach, many have been with the company for years, joining as career changers.

We have very low employee turnover.

The growing demand for specialized and innovative photonics solutions presents new challenges for IMM Photonics, including a lack of production and storage capacity. To meet this demand, an expansion of the Teisnach site is planned.

The planned extension to the existing building will be carried out by the landlord, OZB Teisnach GmbH. “Construction can begin as soon as the organizational prerequisites—such as leasing the upper floor of the planned expansion area—are met,” emphasized Mayor Daniel Graßl.

County Executive Dr. Raith expressed his gratitude during his visit for IMM Photonics’ commitment to the region and emphasized the company’s importance: “The decision to expand in Teisnach is a major asset for the region and strengthens local economic development.”

Published on 10/11/24

An Interview with CEO Christian Raith on Responsibility, Values, and Positive Surprises.

Sustainability is one of the most critical issues companies will face in the coming years, as both politics and society increasingly demand that businesses take on more responsibility in climate and environmental protection. What does this mean for medium-sized companies? Christian Raith, CEO of IMM Photonics, has answers.

What sustainability requirements does IMM Photonics face?

Christian Raith: First of all, it’s important to note that we are relatively unaffected by regulatory requirements, as we neither have high-energy production nor process many hazardous substances. Therefore, our impact is very low compared to other industries. Nevertheless, we have already made many adjustments in the past and are continuing our commitment to sustainability. In this regard, the challenge for us going forward is less about doing even more for the environment and climate than documenting what we’re already doing.

What steps have you taken in your Teisnach production facility for environmental and climate protection?

Christian Raith: For instance, ten years ago, when we built our new facility in Teisnach, we committed to 100 percent LED lighting. Today, that’s standard, but at the time, we were among the pioneers. We operate a woodchip heating system with regional production from the surrounding Bavarian Forest. Our energy strategy also involves maintaining full climate control in production. Humidification in the production area is our primary energy consumer. To avoid excessive heating or cooling from outside, we use 50 percent recirculated indoor air and 50 percent fresh air. Additionally, we use energy from 100 percent green electricity.

Are you purchasing energy, or are you focusing on in-house production?

Christian Raith: We did consider building our own solar farm in the Bavarian Forest—there’s certainly enough space. However, we had to decide against in-house energy production in Teisnach for the time being due to the massive regulatory hurdles.

How do you ensure sustainability is maintained throughout the supply chain?

Christian Raith: We pay very close attention to this point and have established a Code of Conduct with all of our suppliers. After all, sustainability isn’t just about the environment. A core part of it involves human rights, social issues, and how these are managed internally.

And what are your sustainability efforts beyond production and the supply chain?

Christian Raith: This also aligns with our broader strategic direction. Our entire vehicle fleet consists of electric cars, with the only exception being a plug-in hybrid. The building we lease in Unterschleißheim has won a sustainability award, and we actively contribute to efficient energy use there as well. In our offices, we rely 100 percent on LED lighting, and we’ve moved our entire server infrastructure externally to save energy. This has allowed us to reduce our electricity consumption by 50 percent compared to 2020.

Many companies complain about the additional work required by increased documentation and reporting obligations. Do you agree with that sentiment?

Christian Raith: It is indeed an additional administrative burden that’s noticeable. But we’re not doing this without reason; we’re working toward creating a livable future for ourselves, our children, and our grandchildren. As a business owner and a person, this mission is very close to my heart. For example, I am currently working on transforming my private home into an energy-positive house, and I’m proud to say that I’m close to achieving that goal completely.

IMM Photonics is EcoVadis-certified. What does this certification entail, and why is it important to you?

Christian Raith: EcoVadis is an internationally recognized platform that evaluates and helps companies improve their sustainability performance. At the start of the certification process, we had our already implemented measures and existing documentation assessed by EcoVadis. We are proud that we were able to significantly distinguish ourselves from the majority of local companies and received the Bronze award, more or less right from the start. Our short-term goal is to achieve Silver status soon and to continuously improve from there.

People matter

News & Insightspublished on 10/28/24

Skilled professionals are scarce, and demand exceeds supply. IMM Photonics feels this pressure, especially in production and STEM fields. But instead of despairing, this mid-sized technology company has tackled the issue head-on. In our latest article, we explore how IMM Photonics is addressing current challenges and the solutions it has developed.

When we post a job opening, we no longer receive a large volume of applications. And among those we do receive, many incoming applications do not meet our requirements,” says CEO Christian Raith, describing the current situation in the search for new employees. He is aware that he’s not alone in facing this challenge, as numerous other technology companies are competing for highly sought-after talent in STEM fields. Additionally, as a specialist in custom laser solutions, IMM Photonics operates in a true niche market. For Raith and his leadership team, this is a strong incentive to counter the skills shortage through both new and proven approaches.

Three-Round Interviews

Candidates notice a difference from many other companies right at the interview stage. At IMM Photonics, time is taken to get to know applicants thoroughly over three rounds, introduce them to the team, and then hold a final one-on-one conversation. “The feedback is usually extremely positive,” says Raith. He’s even asked new employees later why they chose IMM Photonics. “The answer often was that while we didn’t offer the best package, we made the most effort to connect with them. The appreciation they felt upfront was a key factor—they could see that we genuinely value people.”

Corporate Culture: Tradition Meets Modernity

Once onboard, employees tend to stay. Whether in production in Teisnach or the office in Unterschleißheim, employees at IMM Photonics stay on average for around 13 years. Even longer tenures of 25 years or more are not uncommon. Another indicator of high satisfaction and loyalty is that, despite having the option to work remotely, the Unterschleißheim office is far from empty. Some even make one-and-a-half-hour commutes to work in person with their colleagues. When asked why his employees enjoy working there so much, Raith humbly credits the company’s 25-year corporate culture, which has developed naturally over time. However, he and his leadership team actively work to modernize the culture. They are moving toward a company-wide informal “you,” foster open, level-based communication, organize joint events and excursions, and provide ample opportunities for involvement and growth.

Promoting Openness and Engagement

For a company like IMM Photonics, which continually explores new avenues and develops unique products, it’s essential to create space for creativity and exchange. Both in Unterschleißheim and Teisnach, there’s a shared understanding that conversations at the coffee machine are sometimes more important than those at the conference table. IMM Photonics places great emphasis on personal responsibility and an open, constructive approach to mistakes. “Let’s be realistic: we’ve learned the most from our mistakes. I think that’s something everyone can say about themselves. What matters is drawing lessons from them and emerging stronger,” says Raith. Original ideas and initiatives are encouraged, and everyone is invited to contribute to sustainability efforts—new suggestions are always welcome.

Generational Transition—Planned Over Years

However, the long tenures mentioned above also pose challenges for IMM Photonics. The leadership team is aware that the upcoming generational shift could impact the company significantly if not adequately prepared. To address this, IMM Photonics has created a multi-year program. Each new hire, for example, is paired with an individual mentor, which not only helps them integrate into the company but also proactively facilitates knowledge transfer. Additionally, IMM Photonics invests in its own training programs, expanding beyond business roles to include technical training starting in 2026. “By training employees in technical fields, we can qualify specialists precisely for our needs, reducing the necessity of external hires and cutting both onboarding costs and the risk of mismatched roles,” emphasizes the CEO.

Through partnerships, we aim to connect with others, encourage knowledge exchange, and, of course, introduce young scientists early on to IMM Photonics as a potential employer.

Training Down to the Last Detail

Even when well-trained professionals are hired, the existing team invests a lot of time in internal training and development. For instance, developers come from various fields, such as optics, electrical engineering, or mechanical engineering. ‘Despite their excellent foundational training, new hires very rarely come with exactly the expertise we’re looking for. This means they specialize with us in the area where we need them,’ says CTO Marcus Gögelein. The same applies to the production roles in Teisnach.

Chief Operating Officer Christian Pritzl confirms: “We often spend half a year or more training new employees because the high level of dexterity and expertise required here can’t be found off the shelf.” Beyond this patient and intensive onboarding, IMM Photonics supports individual career paths and offers ongoing development opportunities. These range from language courses and additional training, such as safety specialist certifications, to support for further academic studies.

Attractive Employers are Flexible Employers

A significant challenge, especially for younger employees, is balancing family and work life. IMM Photonics therefore places high value on flexibility in scheduling: “We have 60 people with 30 different work schedules,” CEO Raith chuckles. “In our Teisnach production facility, some start at 6 a.m., while here in Unterschleißheim, some begin at 10 a.m. Employees with children might work in the morning, take a break, and continue in the evening—whether from home or on-site. All of this is possible.”

Helping Save a Piece of the World

Looking forward, IMM Photonics aims to enhance its collaboration with universities, particularly with professors in relevant fields. When asked why he would recommend IMM Photonics to young graduates, CEO Raith doesn’t hesitate: “Because they will find a truly exciting work environment here, where they enjoy a lot of freedom, can contribute significantly, and create something truly new. While we may be just one small cog in the machine of innovative solutions for medicine, bioanalysis, data transmission, or measurement technology, our components contribute a bit toward making the world a better place.